Extreme resistance to chemicals with very strong adhesion and durability. Epoxies are tough potting solutions for the harshest environments and serve as a great deterrent to IP theft.

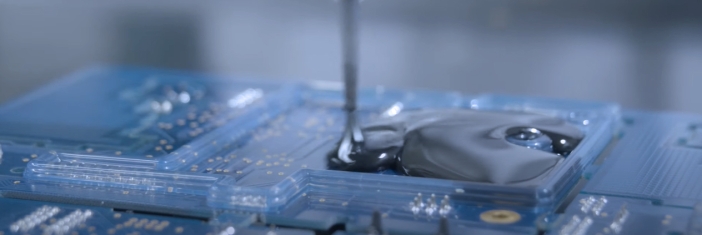

At ECT, we apply potting and encapsulation materials to protect PCBs using robotic dispense systems, and variable ratio, meter mix machines. With our extensive knowledge in the field, we can assist you in finding the most suitable compound to fit your needs and tailor our service to your complex product designs and application requirements.

Potting is typically done directly into a plastic or metal housing which has been designed to hold a PCB and allows for access to properly dispense and degas the mixture through pouring, resulting in superior protection. Our potting services provide protection against physical stress, thermal shock, chemical exposure, heat, and humidity, while providing electrical insulation.

Encapsulation is the localized application of potting applications in a typically thinner amount that cover or “encapsulate” a section or component to provide increased electrical insulation, physical protection, and resistance to environmental extremes.

We bring extensive knowledge on how to select a suitable material and provide contract manufacturing services for potting and encapsulation. The videos shown demonstrate the materials and equipment we can use and sell.

ECT global certifications meet or exceed international and local compliance standards of goods and services.

These are some of the top-performing products, tried and tested by ECT. We can help guide you every step of the way from ideation through to production ensuring the proper material is used in your application.

100% silicone solids elastomer designed for electronic potting applications.

2 Part 2-Part Cure, moderately cross-linked silicone polymer gel used to for potting and encapsulation.

A two-component polyurethane potting and encapsulating compound that carries a UL94 V-0 flammability rating

Premium, UL 94 V-0 recognized fire retardant epoxy potting compound that features excellent electrical properties and long working life.

Blue fluorescing encapsulant/wire bond adhesive with secondary heat cure

We provide service and manufacturing solutions to these six core industries.

We're here to help you find the right solution for your electronic application. Interested in learning more or have questions? Reach out, we want to hear from you!