Replace tape, PSA die-cut, epoxies, silicone, and RTV sealants with top-performing UV/Visible or LED light-curable FIP gaskets. At ECT helps select and apply the best gasket to protect against environmental hazards.

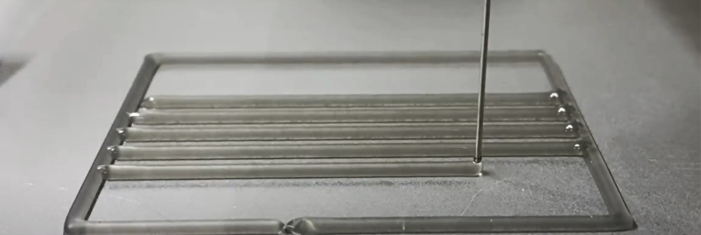

Electronic Coating Technologies applies both electrically conductive and non-conductive form-in-place (FIP) and cured-in-place (CIP) gasketing services. The gaskets are applied as a liquid, gel, or paste utilizing an automated four-axis dispensing system to ensure proper bead dimensions even on complex geometries. The material is then cured using atmospheric moisture, heat, or high-intensity UV/Visible light to form a rubbery or foam gasket. There are a wide variety of materials with different cured properties and conductive filler types.

Electrically conductive form-in-place gaskets are used to aid with the resistance of electromagnetic interference (EMI/RFI) to electronic assemblies. Non-Conductive form-in-place gaskets are used for sealing against moisture and chemical exposure, sound and vibration dampening, and as a contamination barrier between two substrates.

ECT global certifications meet or exceed international and local compliance standards of goods and services.

These are some of the top-performing products, tried and tested by ECT. We can help guide you every step of the way from ideation through to production ensuring the proper material is used in your application.

GA-108 black, light-curable form-in-place (FIP) gasketing resin is formulated for electrical enclosures, HVAC ductwork, and automotive casings applications which require a soft, ticky, flexible gasket with low compression set. GA-108 has good adhesion to plastic, metal, and ceramic surfaces.

GA-142 is a form-in-place (FIP) and cure-in-place (CIP) gasketing resin formulated for electrical enclosures, HVAC ductwork, and automotive casing applications which require a soft, sticky, flexible, low compression set.

Two-component polyurethane adhesive designed to pass UL 94 V-0 flame retardancy testing.

We provide service and manufacturing solutions to these six core industries.

We're here to help you find the right solution for your electronic application. Interested in learning more or have questions? Reach out, we want to hear from you!