Electronic Coating Technologies has been serving the contract conformal coating market for two decades in both Canada and the United States. We take pride in our extensive technical know-how of applying a wide variety of conformal coatings to printed circuit boards using selective conformal coating systems.

Conformal coatings are applied to printed circuit boards (PCBs) to protect them from environmental stress such as salt, corrosion, humidity, and moisture, mitigate tin whiskers, and provide a barrier to electrically insulate components. A wide variety of conformal coating types are available, each with their own strengths and weaknesses.

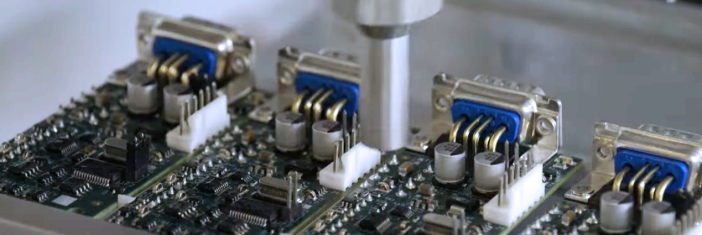

The use of robotic dispensing systems allows us to control our processes ensuring repeatable coating thickness and precise coverage area, which helps eliminate some of the high-cost masking steps typically associated with PCB conformal coating. Repeatability allows us to maintain quick lead times and deliver unprecedented quality control.

We offer a variety of conformal coating types including parylene, acrylics resins, epoxy resins, polyurethane resins, and silicone resins.